Procurement planning for raw materials.

CBT MRP (Material Requirements Planning)

CBT MRP is a tool for planning the replenishment of warehouses and managing procurement, raw materials and supplies in order to maintain optimal stocks in the warehouse.

Organizational procurement planning is the most difficult stage of supply chain management.

Each new project convinces us of the truth of this statement: the department receives information on the amount of need last; change of need occurs most often, for example in packing; most errors of a “human” nature, due to opacity in communications; leverage of raw materials and supplies – the largest in the supply chain; the highest percentage of frozen assets in stock; contractual positions in trading companies; increased requirements for the accuracy of budgeting by the finance department; regular problems with customs; instability in transport orders; the quality of raw materials and many other facts that confirm this.

Procurement planning needs the most planning in the annual planning horizon, so the whole supply chain should have the same horizon.

Speed and accuracy of procurement orders – directly affects the efficiency of the entire supply chain. It is impossible to do this without automatic planning.

Only the automation of the chain will allow you to immediately respond to critical changes and adjust plans. Achieving high data rates between all links in the chain is possible only if the transparency of business processes and their clear relationship.

A single SCM system makes this possible, which will largely allow for the most accurate consideration of influencing factors in procurement planning, such as: a fixed period of production; trade / non-production purchases; optimal level of insurance stocks of raw materials; high level of service for suppliers; maximum inventory turnover; exchange rate; analog raw materials, etc.

CBT MRP

Capabilities.

Take into account all the limitations of the previous stages of supply chain management: sales forecasting and coordination, assessment of sales potential for distribution and production planning;

Record all restrictions on the range of procurement: levels of insurance stocks, min / max batch, multiplicity, leverage, supplier rating, mode of transport, units of measure, quarantine period, etc.;

Record all terms of suppliers: terms and amount of prepayment, work schedule, fixed production period, terms of delivery, deferred payment, etc.;

Use supply chain constraints and conditions to calculate the procurement plan by the sliding method and optimize the result on targets;

Allow to make manual adjustments to the procurement plan and make quick recalculations for different planning scenarios;

Give instant feedback on the previous stages of supply chain planning: production and distribution;

To form the basis and need for transport logistics;

To be the main source for budgeting material costs from short-term to strategic levels;

System description.

Material Requirements Planning (MRP) – planning the need for the purchase of raw materials (СІМ).

MRP tasks:

Maintenance of optimal stocks of raw materials;

Satisfaction of production needs and as a consequence of customer needs;

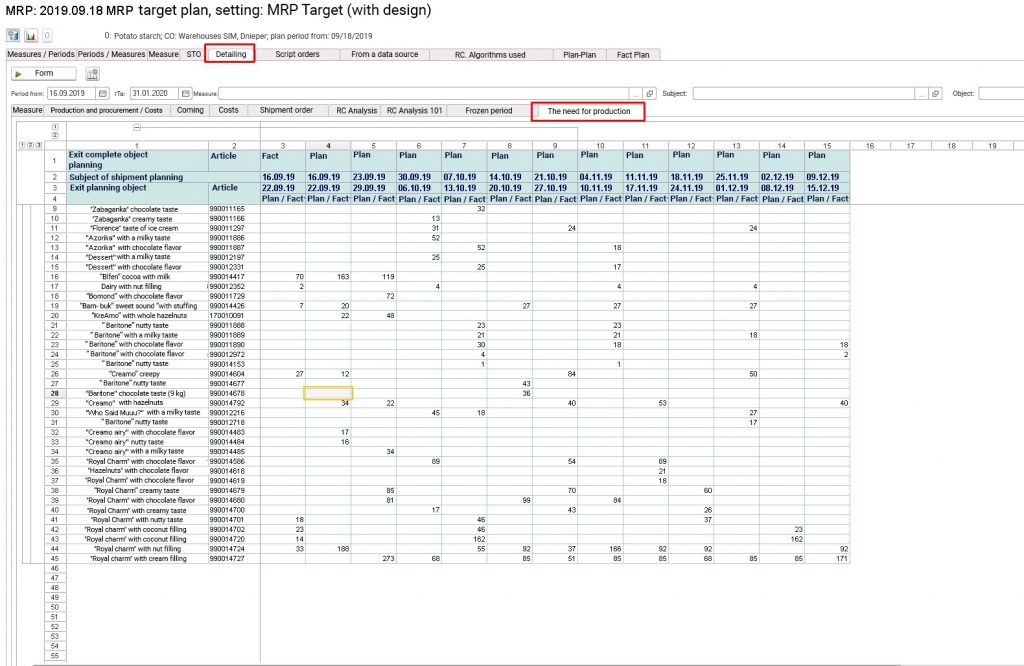

Formation of target needs for production;

Formation of target orders for the purchase of products.

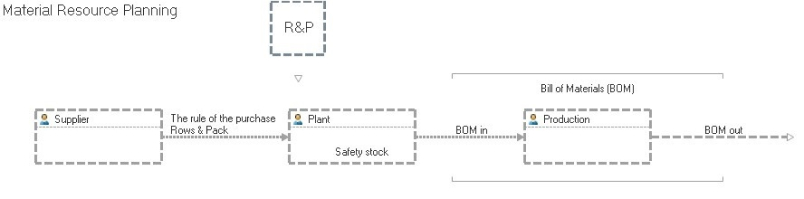

MRP chain map.

A description of all the features of the contractual terms with suppliers is in the chain map.

For one item of raw materials, you can make several purchase cards, from different suppliers or with different terms of delivery. When calculating the algorithm will choose the optimal card for delivery on each of the planned dates.

In the minimum form it is the description of such features of deliveries of production as:

- Minimum batches, multiplicities;

- Procurement / production / relocation / sales schedules;

- Valid rules for expiration dates;

- Required quarantine time;

- Shoulder to purchase.

MRP input management.

At the input, to calculate the next iteration, the MRP system automatically collects and checks for errors the following data:

actual stocks in managed warehouses (operational accounting);

production plans (from the APS subsystem);

stock standards (both in physical terms and in days).

Data Wizard Management.

Once, when deploying the system (and then if necessary), the system will need to make a number of data wizards. For convenience of navigation on this data it is possible to use “MRP settings scheme”. They can also be quickly accessed from reports and reference forms.

R&P – planning objects СІМ;

Supplier – suppliers;

The rule of the purchase RnP – procurement rules;

Plant – warehouses of raw materials;

Production – production sites, work centers.

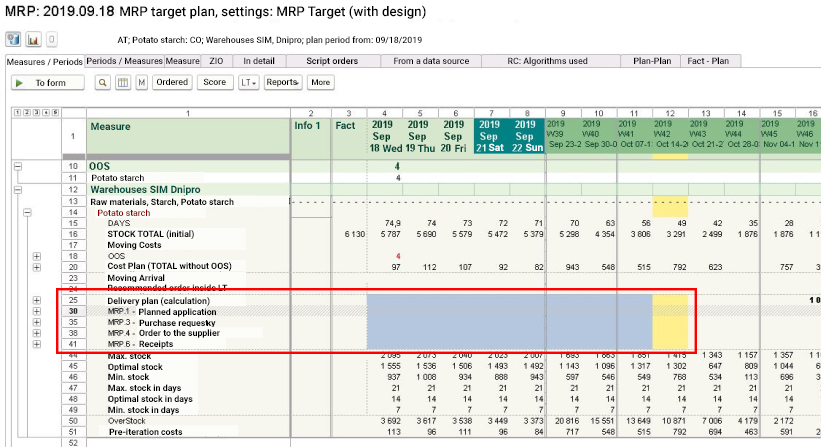

Calculation of MRP chains.

MRP calculation is performed regularly, after the system regularly collects all necessary data. The result of simulated calculations for the entire planning horizon can be analyzed in reports and in the list of orders to suppliers. You can make point adjustments, after which the recalculation is performed.

Each iteration of the calculation can be written to a separate scenario (plan). Thus, due to the flexibility in setting up the system, you can perform several calculations for different scenarios, changing the input information, to further compare and select the optimal calculation settings.

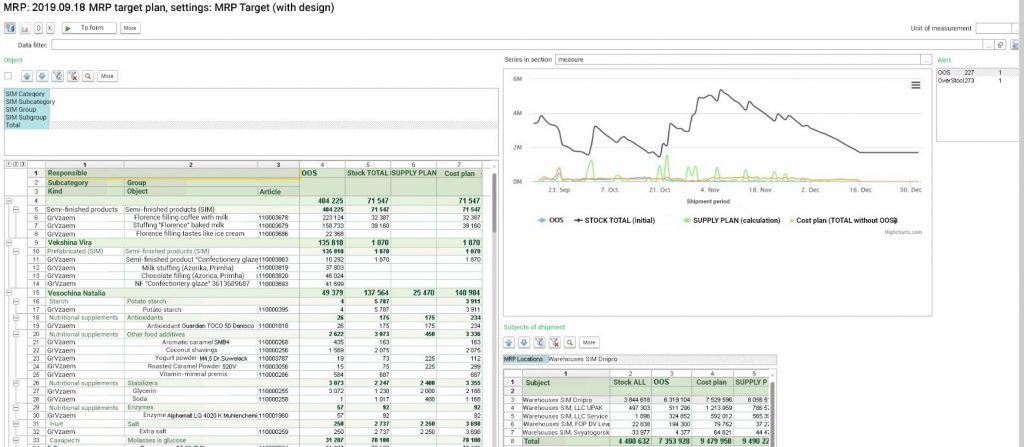

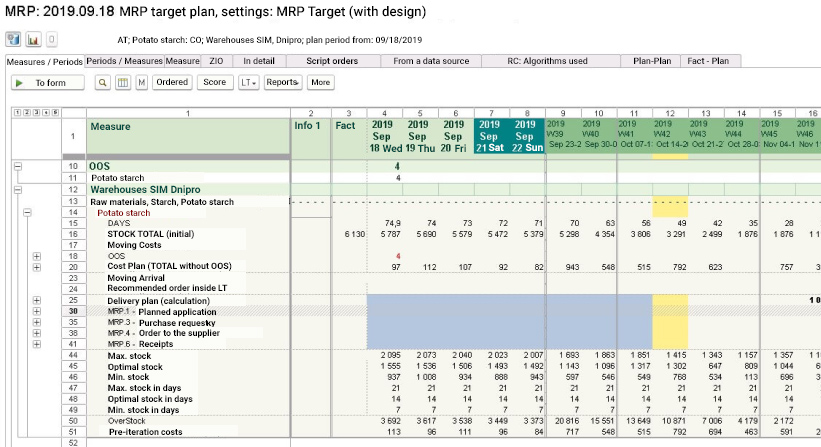

Analysis of the performed calculations can be performed using the DRP report (valid for both target and secured plans).

When performing the calculation, the system may take into account a number of supply restrictions, the main:

adhere to the multiplicity, minimum batch and their size;

permissible qualities of the moved products;

schedules of deliveries and work of subjects;

restrictions on expiration dates;

level of insurance stocks (min, opt, max) in planning warehouses;

time for product delivery.

Complete set of MRP.

Completion of orders – grouping of needs, for movement or purchase, in the order. At a complete set restrictions are considered: transport specifications of the order, the schedule of deliveries, the frozen period, distances between subjects, the schedule of work of subjects.

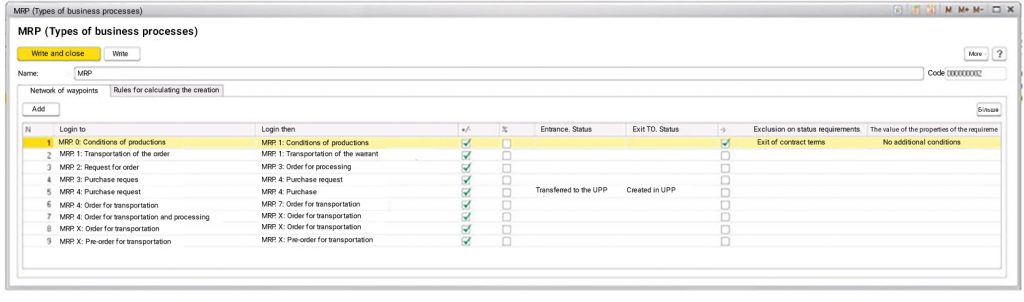

MRP order.

In the system you can configure any business process of working with orders. This includes setting up relationships between different types of orders.

In turn, each order can be customized – customizing both the appearance, features and business process of coordination. The order includes all the necessary reports for their detailed analysis. The history of their adjustments is recorded with the possibility of quick analysis.

MRP reports.

Reports have a flexible and intuitive system of settings and selections. This allows you to customize the report form individually for each user, depending on: the required data sets, sections analyzed, graphical content and visualization of data, which greatly simplifies the work and their initial analysis.

Report “Analysis” – allows you to analyze the grouping of information in terms of objects and subjects, to make selections for specific objects and / or subjects or for those objects / subjects for which the rule of “alarm” worked (Alert).

The report “Measures / Periods”, “Periods / Measures” allows you to display detailed information on those objects and entities for which the selection was imposed in the report “Analysis” .

You can use different reports for a more detailed analysis. For example: to analyze the measures ” Production costs ” you need to generate a report ” Production needs “.

In addition to analysis, the report allows:

- Bring the frozen period to the delivery and delivery arm and, if necessary, change it with the “LT” command;

- Interactively make a value in the measures of arrival to the subject with subsequent automatic recalculation of this item. That is – if the user does not fit the amount offered by the system, he changes this amount to his own and immediately sees the result of how stocks will change in future dates. Based on the selected range in the report with the proposed values before arrival, as well as – based on the values entered by the user, the system allows you to create orders directly from the report (Command “Order”), which automatically fill in the fields: dates of shipment and delivery, subjects shipment and delivery (according to information from circuit maps), planning objects and the quantity that falls into the selected range;

- The command “Calculation”: allows you to recalculate the position, for example, after changing the input data (stocks, movements, master data, etc.);

- Reports command: allows you to generate special reports for in-depth analysis.

Material Requirements Planning

Advantages.

Automated product distribution management

All tasks can be solved by the system regularly (automatically on schedule), without human intervention.

Convenient analytical reports

With instant visualization of changes in charts and reports when making adjustments.

Quick start

You can quickly start working with the program with minimal settings and restrictions with a gradual transition to high detail, more sophisticated forecasting algorithms and dependencies.

Interactive adjustments

All tasks can be solved by the system regularly (automatically on schedule), without human intervention.

Data wizard settings

All tasks can be solved by the system regularly (automatically on schedule), without human intervention.

A solid foundation

Grow the company without increasing the workload to the departments of planning, marketing and sales. Provides opportunities for the development of forecasting algorithms. Open source.

Customers who trust us.

What goals can you achieve?

Reduce the duration of the operational sales planning cycle

Increasing the speed of response to changes in the environment and operational information (up to 2-3 hours per day, several iterations of adjustments per day instead of 1-2 times a week earlier and partial daily / weekly rescheduling).

Improving the efficiency of capital use

material, human and other resources through centralized inventory management, sales plans, distribution of products and raw materials

The general decrease in the level of stocks in the system

About 30%.

Faster and deeper analysis

stocks, demand, distribution of raw materials and finished products and their dynamics, with the same or less human resources, the creation of several parallel scenarios for sales forecast and distribution of products.

Strengthening the control of the correctness of the tasks of the automated system

automatic calculations, visual inspection of inventory levels and planning accuracy, analysis of changes in plans for sales, supply, production and distribution of products.

Portfolio.

Reviews.

The SCM scheduling tool reduced the operational scheduling cycle to 1-2 hours per day, allowing several iterations of adjustments per day instead of 2 times a week earlier and only partial daily rescheduling; reduce the staff of planning managers from 8 people to 3 people; conduct in-depth analysis with fewer resources, and receive operational calculations instantly; reduce inventory levels by 30%!

At the same time to increase the level of customer support by 2-3%, which is currently 96-98%; We were able to increase the freshness of products for shipment to customers by 33% and reduce the level of write-offs of expired products in warehouses by 17%; strengthen control over the correctness of the tasks of the automated system through automatic calculations, visual inspection of inventory levels, analysis of changes in plans and incoming data. The implementation of the CBT SCM software solution has contributed to the growth of the business, and the results have exceeded our expectations.

Special algorithms have been developed for Danone Ukraine to take into account the specifics of production, storage and distribution of perishable, as well as shelf life management. Under these conditions, the response time to changes in needs or production plans may not be calculated in days or weeks to manage replenishment.

The SCM scheduling tool reduced the operational scheduling cycle to 1-2 hours per day, allowing several iterations of adjustments per day instead of 2 times a week earlier and only partial daily rescheduling; reduce the staff of planning managers from 8 people to 3 people; conduct in-depth analysis with fewer resources, and receive operational calculations instantly; reduce inventory levels by 30%!

At the same time to increase the level of customer support by 2-3%, which is currently 96-98%; We were able to increase the freshness of products for shipment to customers by 33% and reduce the level of write-offs of expired products in warehouses by 17%; strengthen control over the correctness of the tasks of the automated system through automatic calculations, visual inspection of inventory levels, analysis of changes in plans and incoming data. The implementation of the CBT SCM software solution has contributed to the growth of the business, and the results have exceeded our expectations.